Services

At JOMER SID USA, we offer a wide range of specialized industrial services designed to ensure the optimal performance and maintenance of machinery across various sectors, with a particular focus on the sugar industry. Our team of experts specializes in machining and hardfacing of rolls, fabrication of cane truck hoppers, manual and automatic welding, and manufacturing of key industrial components such as helical conveyors and juice heaters. Additionally, we provide lubrication and monitoring services and perform non-destructive testing to guarantee the integrity of each component without compromising its structure. Our commitment to quality and technical innovation positions us as a trusted partner in developing customized solutions for each project.

Industrial Maintenance and Manufacturing

• On-site Hard Coating and Teardrop: Specialized service to ensure the durability of industrial components.

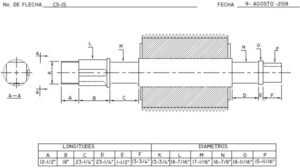

• Machining and coating of sugar cane rollers.

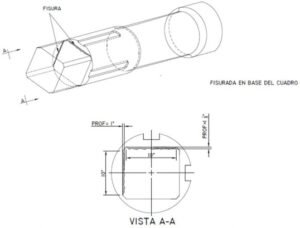

• Fluting of rollers and steel shafts.

Manufacture of staves for conveyors: Specialized process to ensure efficient operation in conveyor systems.

Specialized Welding

• Welding with coated electrode or automatic wire.

• Manual welding applications adapted to specialized technical requirements.

Hardfacing and Teardrop in situ: Specialized application to improve the durability of components.

Machining and hardfacing sugar cane roll: Ensuring precision and longevity for each piece.

Grooving roll and steel shaft: Advanced technical services to optimize roller and shaft performance.

Welding with stick electrode or automatic wire: Advanced techniques for efficient welding.

Manual welding application: Adapted to specialized technical requirements.

Manufacturing and Coating

• Flanges: Manufacturing and homogeneous coating to prevent deformation (A36 Plate from 2” to 3”, CR carbide coating).

• Pipes and structures: Custom solutions for various industrial applications.

Manufacturing and coating of flanges: Machining for homogeneous application that avoids deformation. Base material: Plate A36 from 2” to 3”. Shielding: CR carbide.

Pipe and structures: Customized solutions tailored to industrial needs.

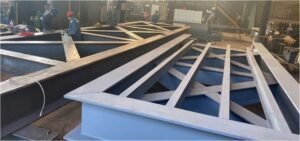

Fabrication of Sugar Cane Truck Hoppers

• 9-meter and 20-meter hoppers, ensuring robustness and efficiency in every piece.

9-meter cane truck dump fabrication: Robust and efficient construction.

20-meter cane truck dump fabrication: Designed for durability and industrial use.

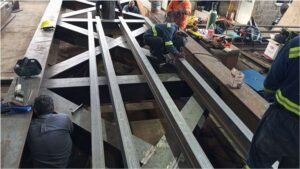

Assembly and Installation

• Assembly of structures and cranes.

• Manufacture of bases for sugar cane shredder turbines.

• Helical conveyors and Donnelly conveyors.

Helical conveyor manufacturing: Solutions for efficient material transport across various industries.

Juice heater manufacturing: Designed for high-efficiency processes.

Calandria manufacturing: Essential components for juice handling in the industry.

Donnelly conveyor manufacturing: Optimized solutions for material handling in the sugar industry.

Sugar mill shredder liners and manufacturing: Specialized fabrication to extend the lifespan of mills.

Manufacturing of blades, hammers, and trash plates: High precision to meet the most demanding industry standards.

Additional Services

• Repair of steel shafts and grinding of bearing seats.

• Lubrication service, supply, and monitoring to ensure proper machine operation.

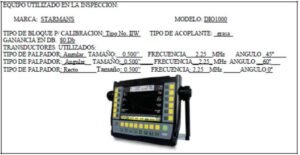

• Non-destructive testing to ensure component integrity without affecting use.

Steel shaft repair: Specialized service to ensure the structural integrity of shafts.

Shaft bearing seat grinding: Precision machining to optimize performance.

Lubrication service, supply, and monitoring: Ensures proper machinery function and maintenance.

Non-destructive testing: Tests to ensure component integrity without compromising usability.

What’s your project?

Tell us how we can help and schedule a call with one of our experts to learn more about how we can boost your industry.